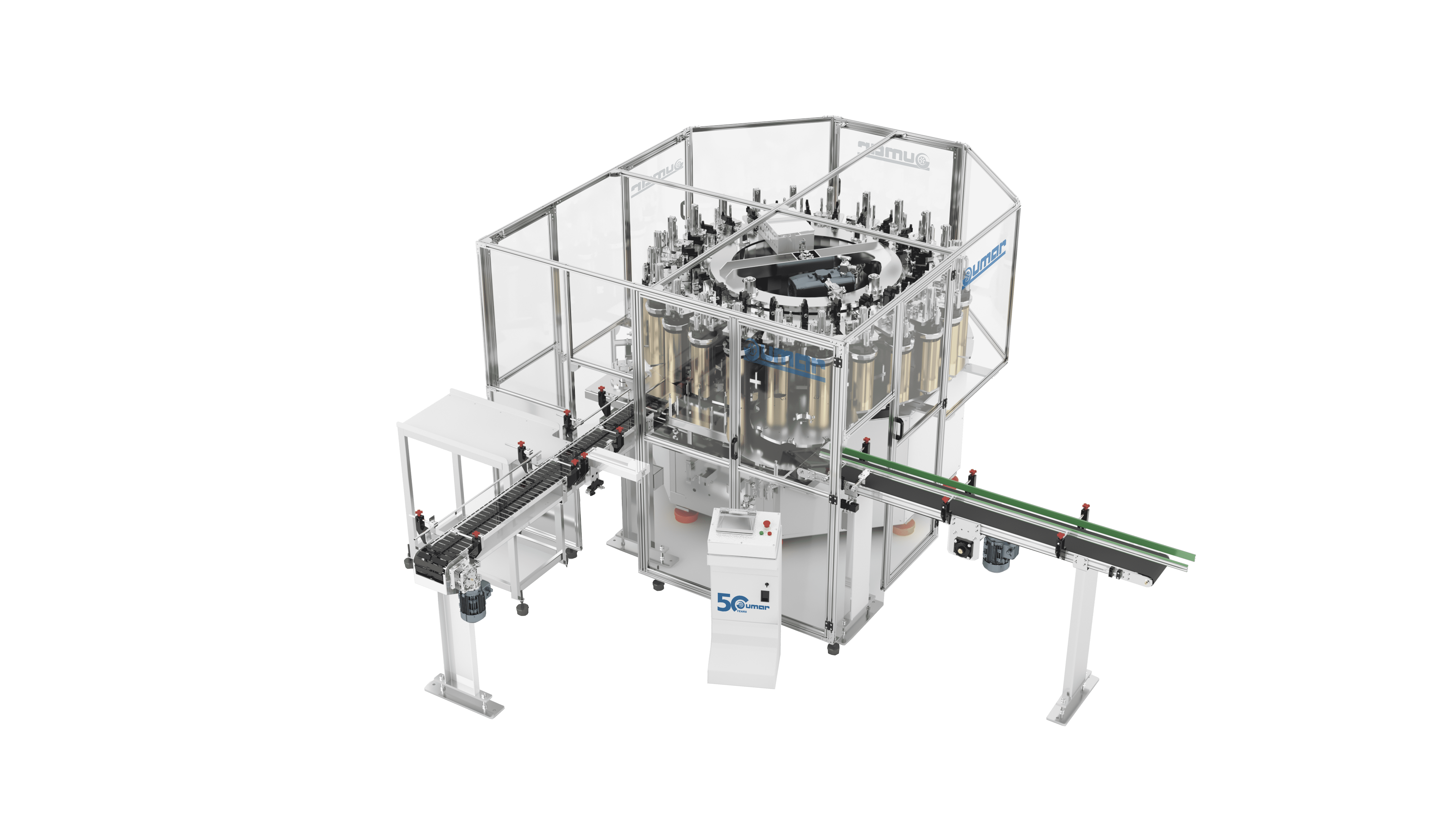

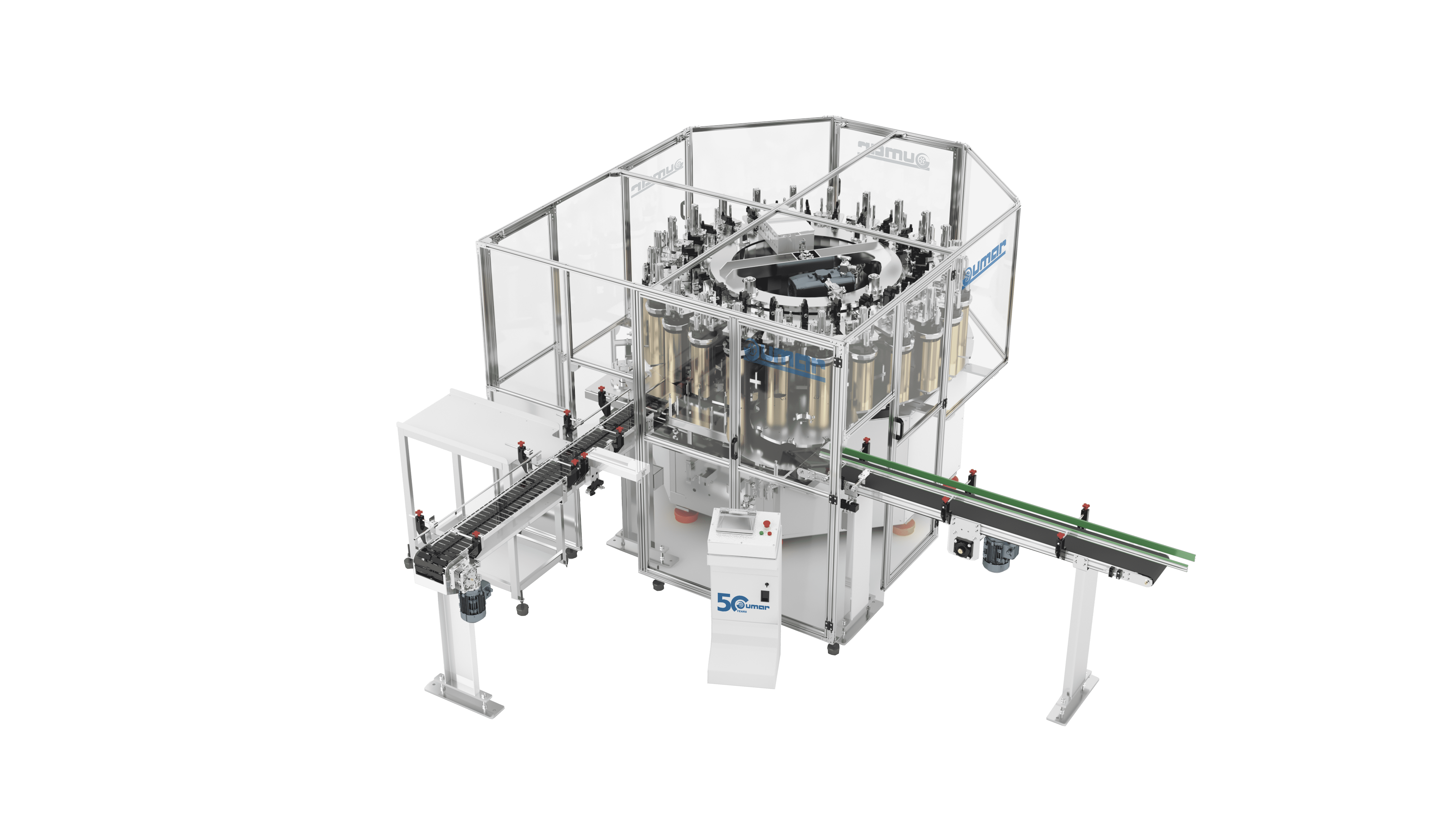

Leak Tester

Leak Tester

The Tin Can Vacuum Tester Machine is designed for vacuum testing of Round Cans, Irregular Cans, and Conical Pails using high-precision pressure decay technology. Ideal for post-assembly quality control, this machine ensures every can is leak-free before final packaging.

| Model | Capacity (cans/min) | Testing Stations (Heads) | Body Height (mm) | Body Dimensions (mm) |

|---|---|---|---|---|

| MAC 08721 | 45 – 55 | 18 – 24 | 120 – 360 | 43 × 60 to 235 × 235 |

| MAC 08621 | 45 – 55 | 18 – 24 | 120 – 360 | Ø73 – Ø310 |

Fill out our form to get more detailed information about our products. We will get back to you as soon as possible during our business hours. By learning more about our products, we will help you choose the option that best suits your needs.

Umar Bildirim Merkezi

Umar Bildirim Merkezi