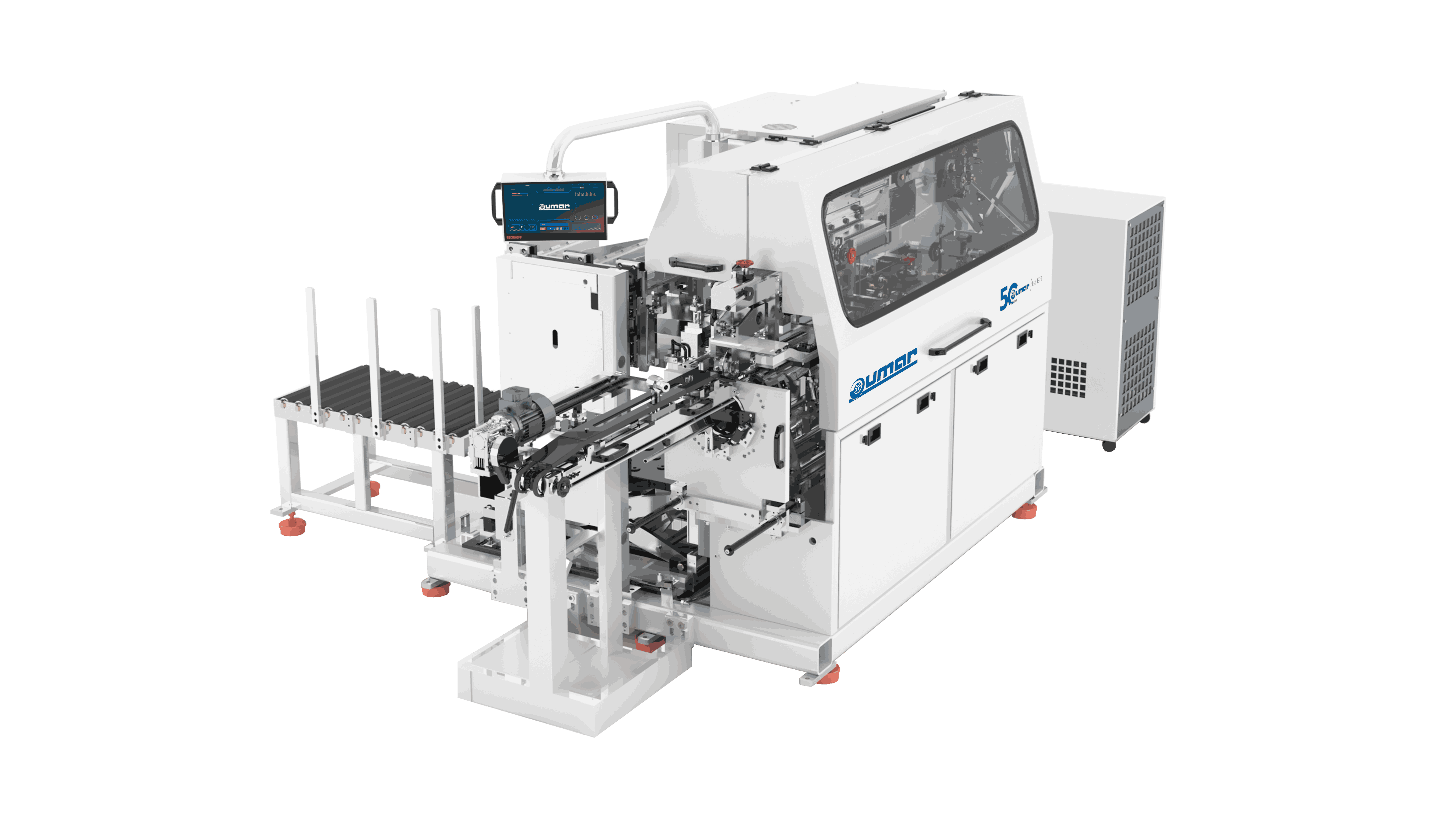

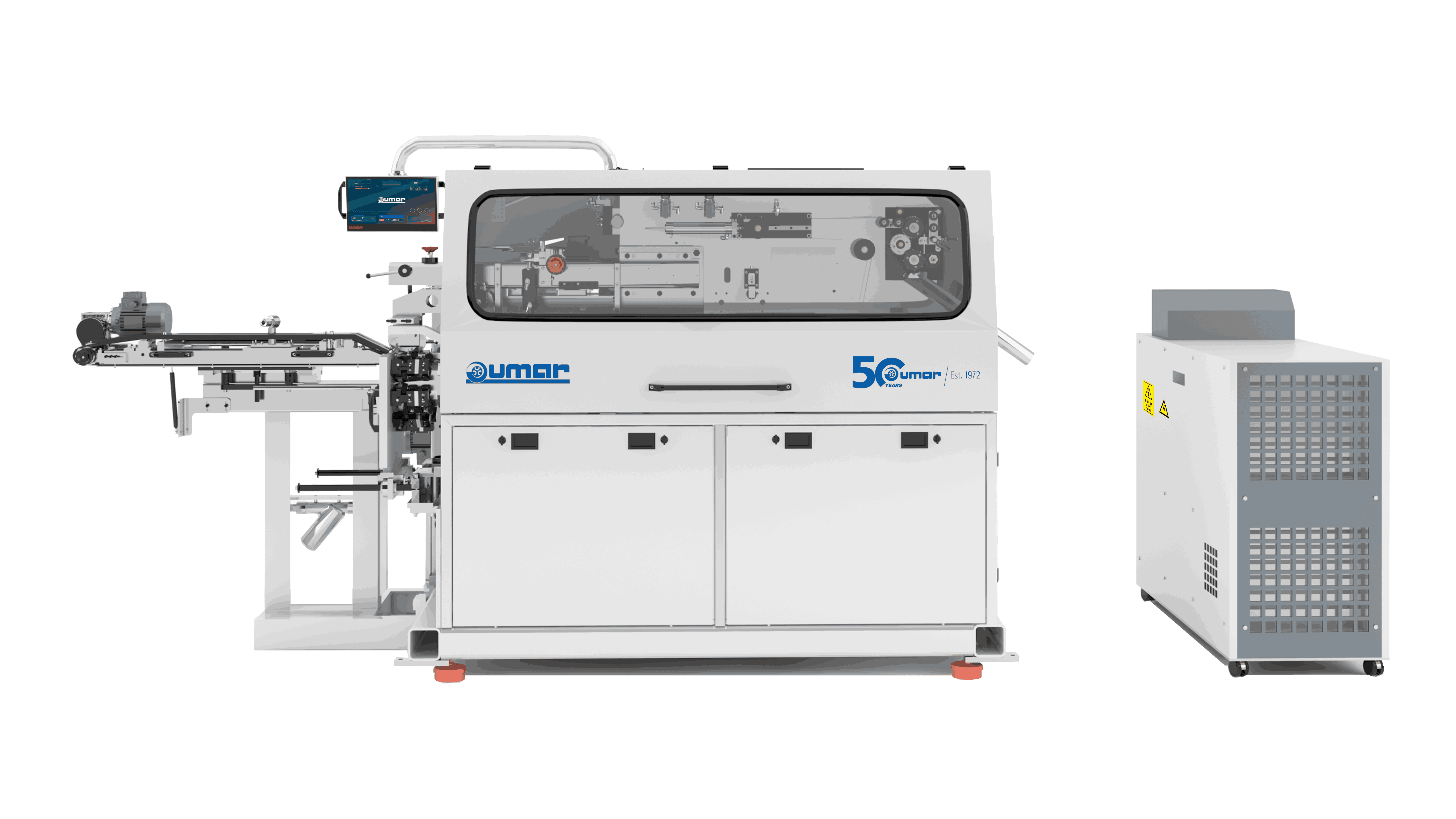

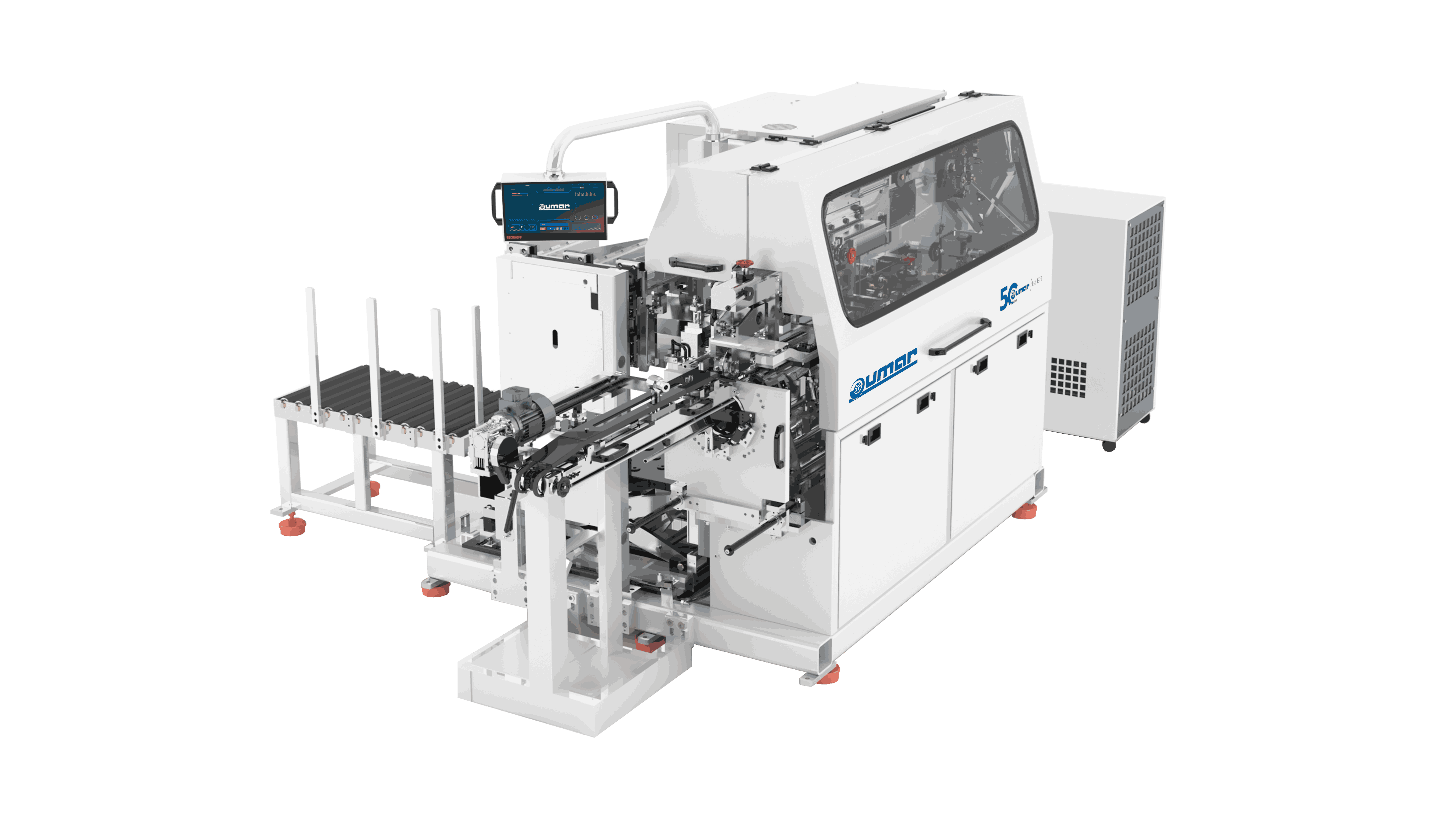

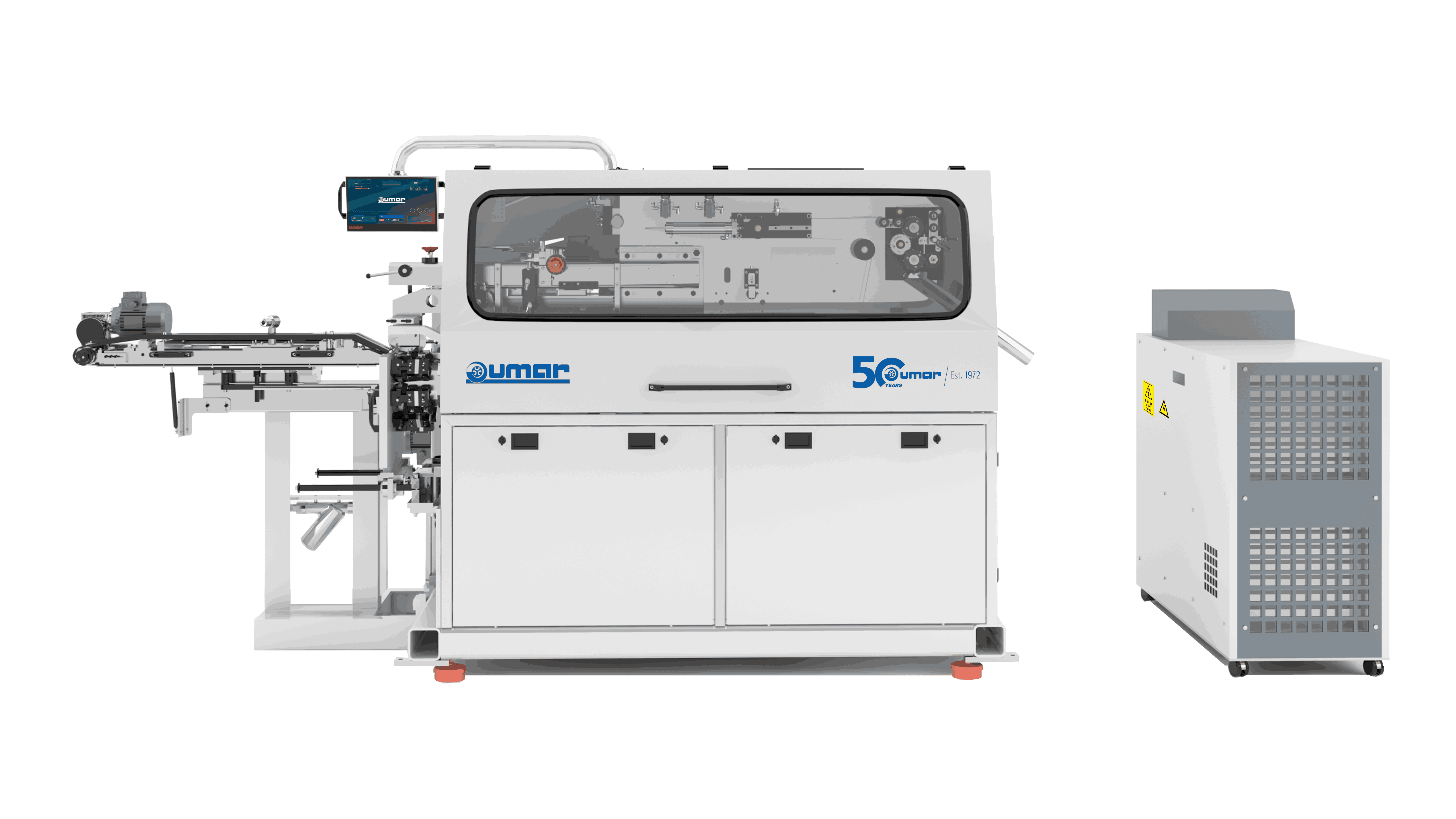

MAC Series - Fully Automatic Can Body Welder

For Cylindrical Shaping and Seam Welding of Three-Piece Can Bodies The MAC Series

Can Body Welder is the core of the three-piece can production line—automatically rolling flat body blanks into cylindrical shapes and performing high-precision seam welding. Built with the latest mechanical, electrical, and software technologies, it delivers speed, flexibility, and long-term reliability.

Key Features & Advantages

-

Fully Automatic Operation: Developed for high-speed, consistent production of welded can bodies with minimal manual intervention.

-

Quick Diameter Changeovers: Switch between can sizes in record time with an easy-change calibration unit, reducing downtime and boosting productivity.

- Smart Industrial Integration: Equipped with a powerful industrial PC and advanced software, the MAC Series is Industry 4.0 ready—allowing full monitoring and remote access via smart devices from anywhere in the world. Online service and remote software updates ensure seamless operation and support.

- User-Friendly Interface: A 15” touch screen with an intuitive, multilingual interface makes operations simple and efficient for operators at all skill levels.

- Precision Feeding: Servo-driven linear axis ensures accurate and stable feeding of can bodies to the welding rollers.

- Efficient Welding System:

- Mercury-free welding rollers with closed-circuit cooling system for longer service life.

- Static frequency converter optimizes welding current distribution while keeping energy consumption low.

- Electronic control of welding current and speed for consistent seam quality.

- Delivers oxide-free weld seams ready for further downstream processing.

- Compact, Modern Design: Built on a stable, space-saving frame, the machine features easy maintenance access, wide use of commercial components, and full protective covers for operator safety.

- Advanced PLC-Controlled System: All movements are handled by independent brushless motors, precisely managed via PLC. Includes monitoring for double sheet detection, wire break, low air pressure, cooling water conditions, and more. Stores individual can formats as parameter presets for fast recall and repeatable accuracy.

Integrated Systems Included

- External water cooling unit

- Output conveyor unit

- Movable, ergonomic control panel

- Ready interface for powder coating integration

- Interchangeable calibration unit compatible with U-Discon or AMS rollers

Optional Add-ons

- Automatic blank transfer system from slitter to welder

- Online welding quality control and faulty can ejection system

- Full line control of slitter, transfer, side seam protection, and curing oven from welder interface

Technical Specifications

| Model | MAC 20640 | MAC 20655 | MAC 20332 (Non-Stop) |

|---|

| Capacity (bodies/min) | 60 | 80 | 120 |

| Can Diameter (mm) | Ø140–295 | Ø140–295 / Ø84–230 | Ø84–153 |

| Body Length (mm) | 100–530 | 100–380 | 50–320 |

| Tinplate Thickness (mm) | 0.20–0.40 | 0.20–0.40 | 0.18–0.30 |

| Copper Wire Ø (mm) | Ø1.38–1.50 | Ø1.38–1.50 | Ø1.38–1.50 |

| Welding Speed (m/min) | 12–21 | 12–21 | 12–21 |

* Actual output depends on can diameter and body length.

Umar Bildirim Merkezi

Umar Bildirim Merkezi